Product number:

20153300

SP30/9R-D Air Nutrunner

Applications

This air nutrunner motor is intended for installation in bolting units and assembly systems with one or more tightening spindles and its design makes it ideal for use in industrial automation. It can also be installed in single station solutions with multi-spindle units. Possible applications would be the use in automatic assembly lines, rotary indexing machines, multiple screwdriving units and screw slides as well as the integration in robot arms.

Air nutrunner SP30/9R-D with slip clutch, clockwise rotation

Torque range: 1.5 - 4.5 Nm / 3.5 - 9.5 NmSpeed: 1,000 min-1

Power: 300 W

Clockwise running direction to screw in.

Direct start via a remote control valve (one compressed air inlet).

Air control via an external 3-way control valve.

Air nutrunner motors with slip clutch are versatile and therefore the best solution when assembling many types of materials. Even when assembling different qualities, these screwdriver spindles offer a lot of flexibility. Especially when using self-tapping screws, air nutrunner motors with slip clutch are the first choice.

There is no risk of overheating with these rugged, high-performance air nutrunner motors.

Even with continuous operation, frequent starts/stops or, if necessary, reversal of the direction of rotation (UD types), they provide constant performance over the long term, even under the most severe operating conditions.

By using high-quality components and materials, the tightening spindles have a long service life and low maintenance costs.

The installed thrust bearings withstand the demands of automated production cycles.

The low space requirement and low weight also allow installation in multiple screw spindle units.

The recessed nutrunner motor is equipped with a safety bush, which prevents the accessories from accidentally falling out during difficult production cycles.

The air nutrunner motor has the ideal design for mounting in your machines.

Connection to an oil separator to reduce oil mist emissions is possible.

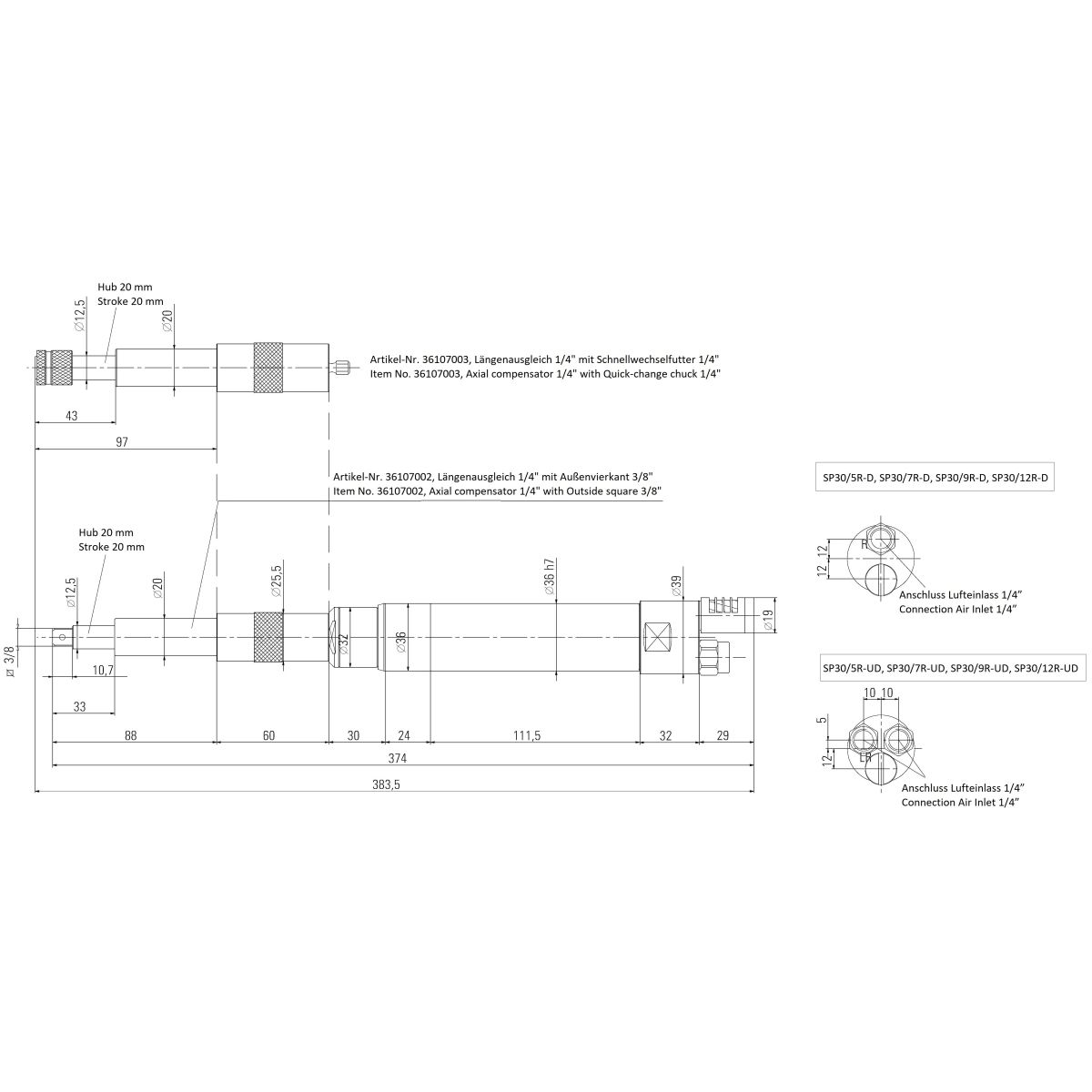

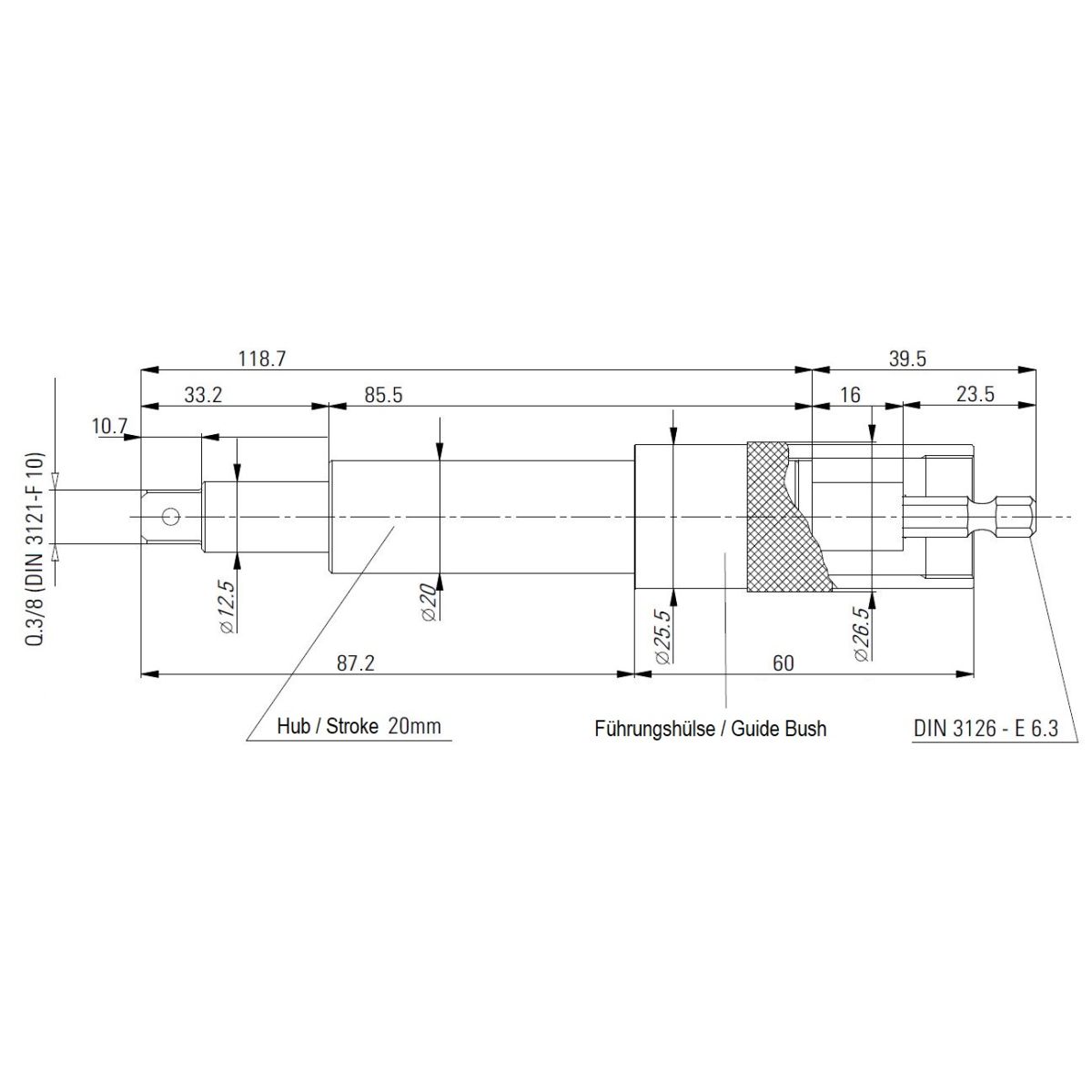

In the accessories you will find suitable length compensators to compensate for any height differences of the screws. They reduce the axial pressure on the mechanical part of the motor, protect the internal components and increase the service life.

| Antrieb: | Druckluft |

|---|---|

| Werkzeugform: | Gerade |

| Start: | Direkt über externes Steuerventil (3-Wege) |

| Kupplung: | Rutschkupplung |

| Leistung: | 300 |

| Drehmomentbereich: | 1.5 - 9.5 |

| Betriebsdruck: | 6.3 |

| Schalldruckpegel: | 77 |

| Luftverbrauch: | 9.0 |

| Empf. Schlauch-Ø: | 9 |

| Signalanschluss: | M5 |

| Gewicht: | 0.85 |

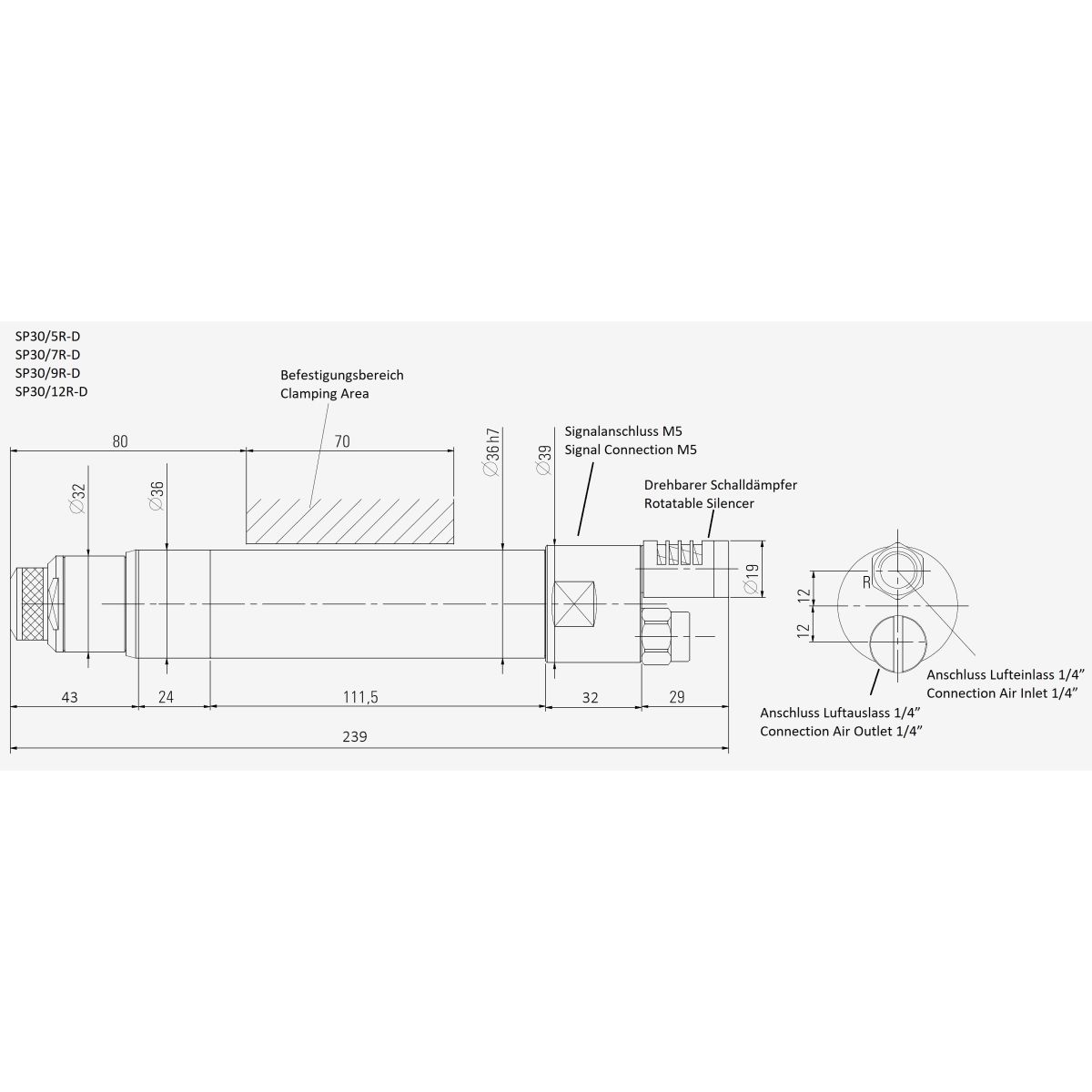

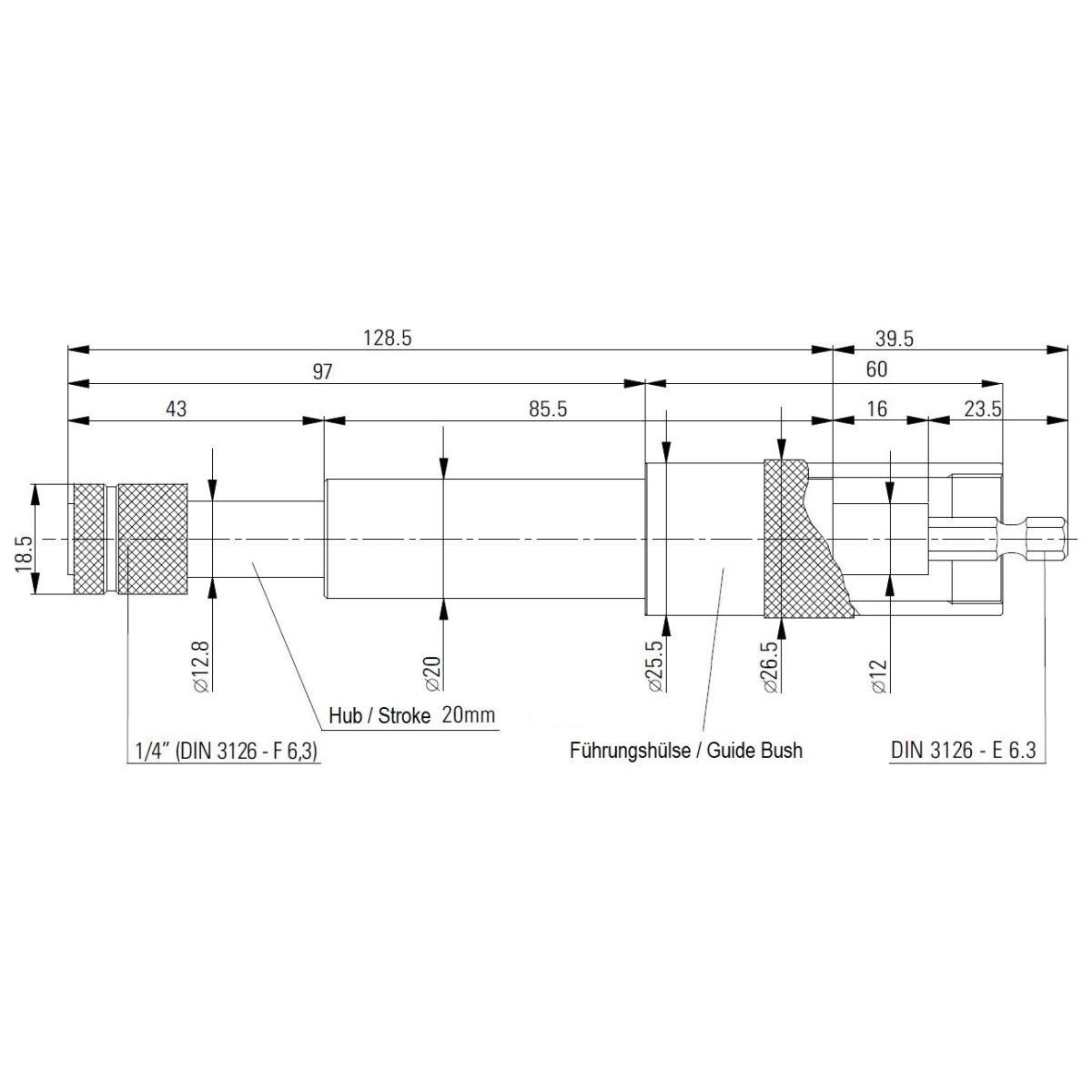

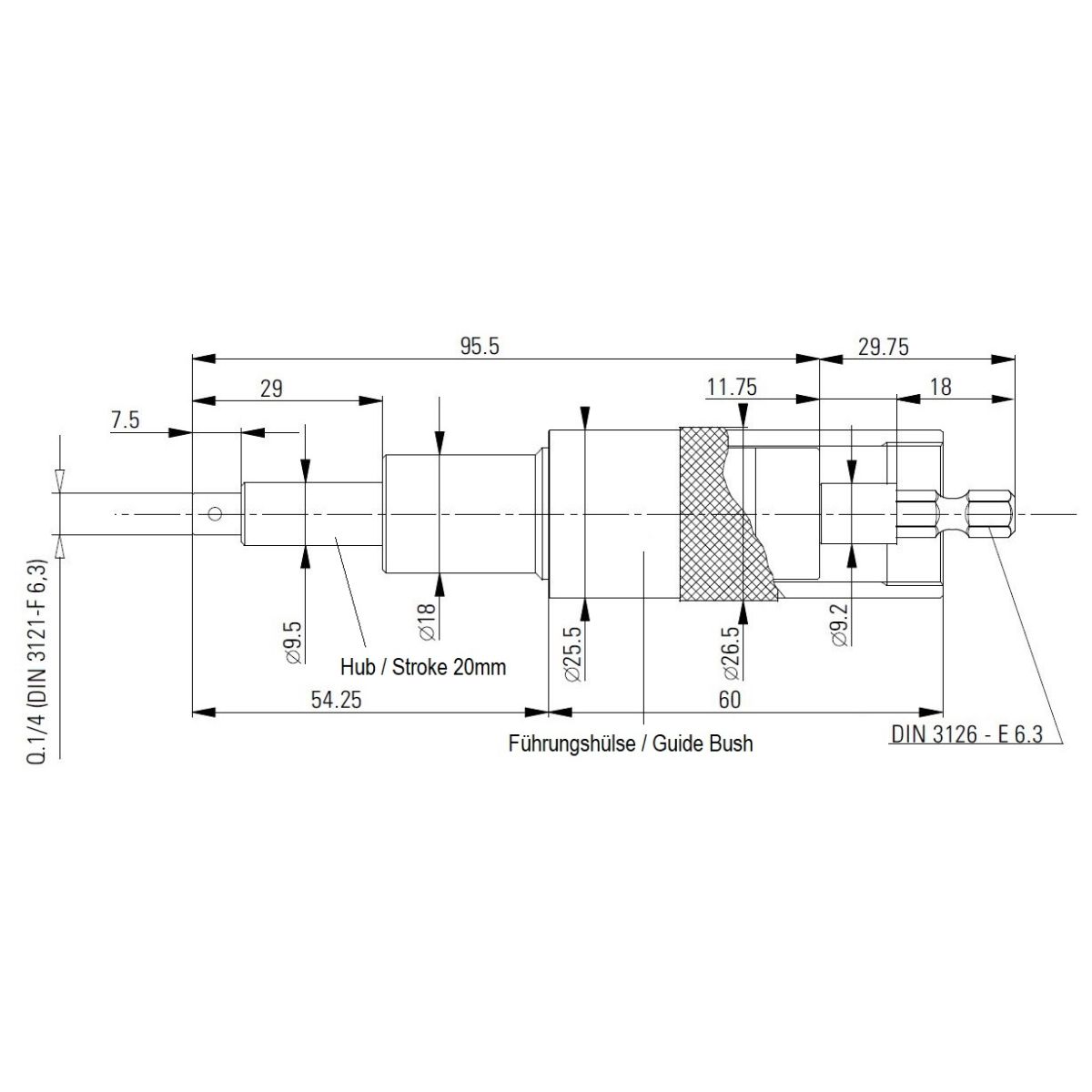

| Länge: | 239 |

| Gehäuse Ø: | 36 h7 |

| Drehrichtung: | rechtsdrehend |

| Drehzahl: | 1000 |

| Air consumption: | 9.0 l/s |

| Anschluss Zuluft: | G 1/4" |

| Aufnahme: | Klingenaufnahme, Innensechskant 1/4" (6,35 mm) |

| Chuck: | Standard chuck, female hex. 1/4" (6.35 mm) |

| Clutch: | Slip Clutch |

| Construction form: | Straight |

| Current: | Pneumatic |

| Direction of rotation: | clockwise |

| Drehmoment Feder: | eingbaut / mitgeliefert1.5 - 4.5 / 3.5 - 9.5 |

| Housing Ø: | 36 h7 mm |

| Inlet air connection: | G 1/4" |

| Length: | 239 mm |

| P_Max. Betriebsdruck: | 6.3 bar |

| Power: | 300 W |

| Recommended hose Ø: | 9 mm |

| Signal connection: | M5 |

| Sound pressure level: | 77 dB(A) |

| Speed: | 1000 min-1 |

| Start: | Direct by external control valve (3-way) |

| Torque range: | 1.5 - 9.5 Nm |

| Torque range spring: | assembled / optional1.5 - 4.5 / 3.5 - 9.5 Nm |

| Weight: | 0.85 kg |